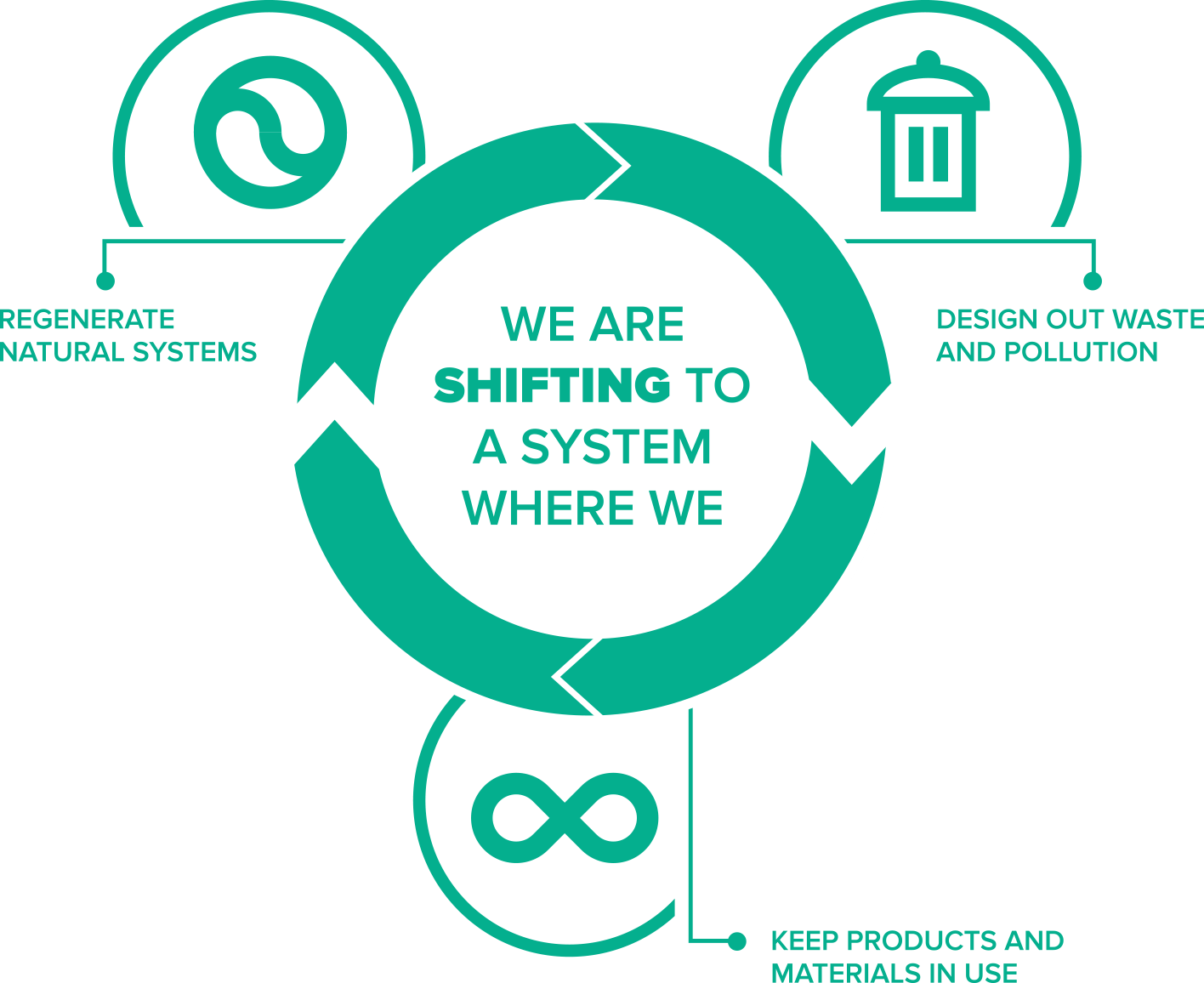

Eliminating waste and pollution starts from the moment the design process is undertaken. At Piper & Skye, we have gone to great lengths to design luxury handbags that will have minimal impact on the environment once/if they reach the end of their useful life.

100% Biodegradable - By designing our bags in 100% biodegradable pirarucu leather, they will have no lasting negative impact on the environment once they reach the end of their useful life.

Dematerialization - Using less material means that ultimately, less waste is produced and fewer resources are removed from Mother Nature. Throughout the design process, we are always asking ourselves how we can do more with less.

Interchangeable Components - Many of our handbags are designed with interchangeable components such as crossbody straps. This allows for them to be worn in a variety of different ways so that instead of having to buy two different bags, just one will do. The result is less consumption, and ultimately, less waste.